Product Description

Model NO.: UL-P4040 Salt Rejection Rate: 99.5% Performance: Sophisticated Filters Motive Force: Electric Power Origin: China Certification: CE Application: Industry Type:

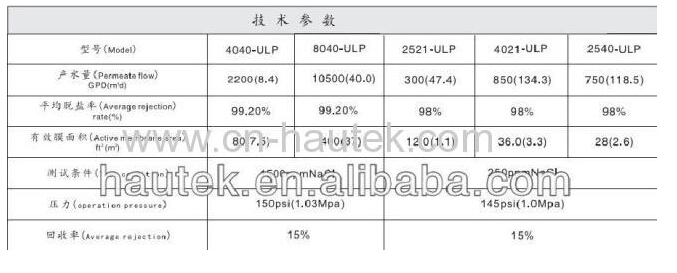

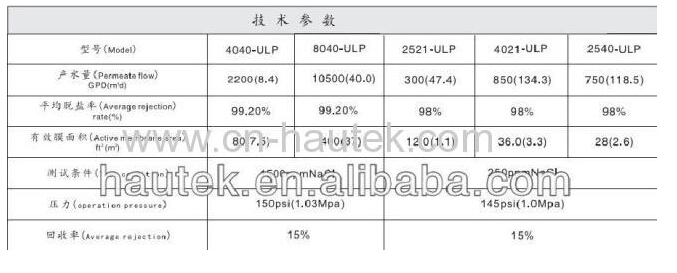

Reverse Osmosis Trademark: Hautek HS Code: 8421999000 1.ULP ( Ultra Low Pressure ) series is the latest research and development of environmental protection for surface water and groundwater desalting super low aromatic polyamide composite membrane element, to ultra low operating pressure conditions hit and conventional low-pressure membrane the same high water flux and high desalination rate. The operation pressure of about conventional low voltage composite membrane operation pressure of 2 / 3, desalination rate up to 99.5% and thus reduce the associated pumps, piping, vessels and other investment cost of the equipment and reverse osmosis system operating costs, enhance economic efficiency. 2. ULP series of membrane element is applied to the salinity of about 2000ppm below the surface water, groundwater, water and municipal water, water desalination, mainly used in a variety of sizes of pure water, boiler water supply, food processing and pharmaceutical manufacturing industry and other fields 3. Important information 1-For any recommended design scope,please refer to the latest version of technical manual, design guide, or consult experts proficient in membrane technology.In case the customer fails to follow the operating conditions as specified in this manual, Hangzhou HaiNa environmental protection Technology Co., Ltd. will assumes no liability for all results. 2-The permeate flow listed in the table is the average value. The difference between the lowest permeate flow of single membrane element and nominal flow is not larger than 20%. 3-Before leaving the factory, all wet membrane elements will have been strictly tested, and have been treated for storage with the solution of 1.0% sodium hydrogen sulfite (anantifreeze solution of 10% propanediol will further added in winter), then packed in vacuum, and outer packing is carton. In order to prevent the breeding of micriobes during short-time storage, transportation and system standby, we recommend you to soak the membrane elements with the protective solution (prepared with RO permeate water) containing 1.0% sodium hydrogen sulfite (foodstuff-purpose). 4-Discard RO product water produced during the first one hour after system start-up. 5-During storage time and run time, it is strictly prohibited to add any chemical medicament, which may be harmful to membrane elements. In case of any violation in using this kind of chemical medicament, Hangzhou HaiNa environmental protection Technology Co., Ltd. assumes no liability for all results. 4. The matters needing attention 1-All data and information provided in this manual is obtained from long-time experiment by HaiNa. environmental protection Technology Co., Ltd. We believe the data and information contained herein to be accurate and effective. However, since the conditions and methods for using of our products are beyond our control, HaiNa. environmental protection Technology Co., Ltd. assumes no liability for all results obtained through the application of the presented data and information. Clients should use the membrane strictly according with the requirements of products design, operation and maintainance. And user should also keep the relevant record. 2-Due to technology development and products renovation, products information will be subject to modification without prior notification. Please pay attention to HaiNa's latest products information.

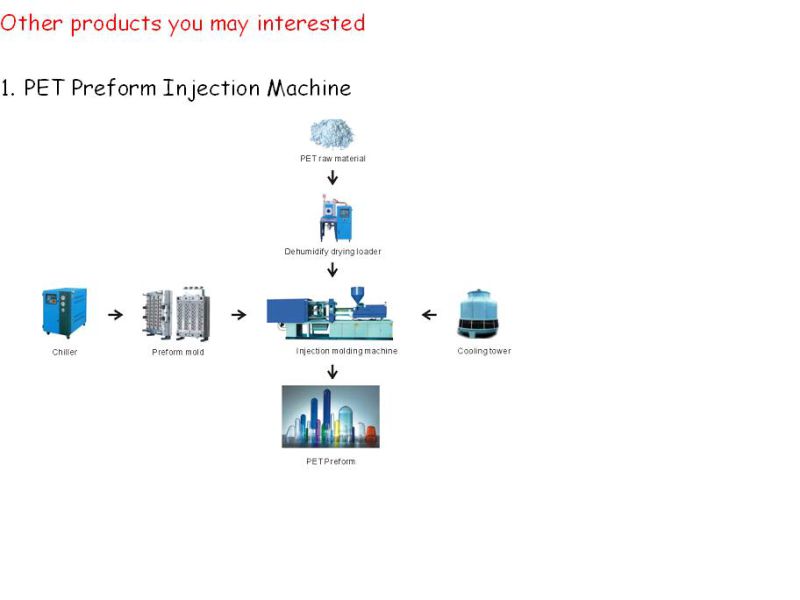

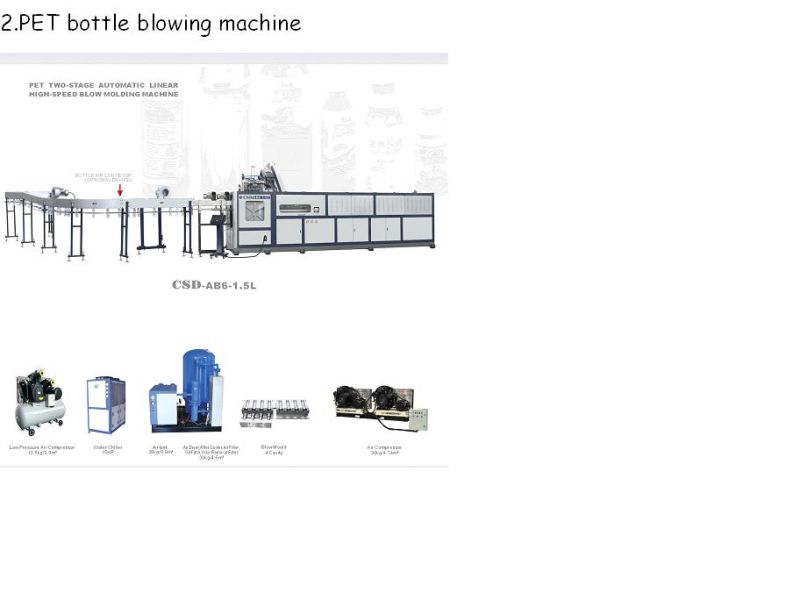

Company Brief: Based on more than 15 years of professional machinery exporting experience, with rich knowledge of beverage project, bottling technology and bottle making machinery, HAUTEK focuses on high and middle level international market, major in beverage production line design and manufacturing, also supply relative assorted equipment. Supported by strong technical team, we offer high quality machine, good service to customers and give prompt response. We have had success in exporting and installation many beverage production lines abroad. Some projects abroad of Hautek: 2001Nigeria: 200BPH 5Gallon water bottling and 3,000BPH water bottling plant. 2003Sri Lanka: 3,000BPH carbonated beverage production line. 2003Maldives: 3,000BPH

Water bottling line (with seawater desalination) 2005Sri Lanka: 12,000BPH carbonated beverage production line. 2006Nigeria: 9,000BPH water bottling production line. 2006Libya: 2,000BPH water bottling production line. 2007Angola: 9,000BPH water bottling production line. 2008Russia: 12,000BPH*2 water bottling plant. 2009Rwanda: 3,000BPH water bottling production line. 2010Yemen: 9,000BPH water bottling plant. 2011Cameroun: 2,000BPH water bottling production line. 2012Nigeria: 12,000BPH water bottling plant.

Contact us if you need more details on RO Membrane. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Membrane、Water Filter. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : RO products