Product Description

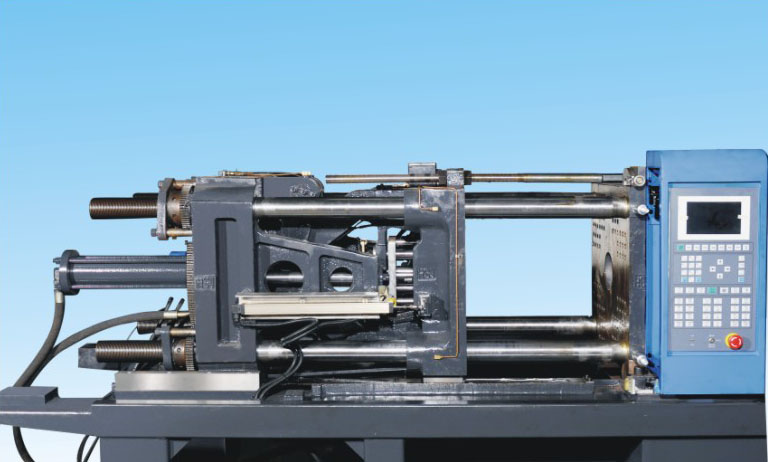

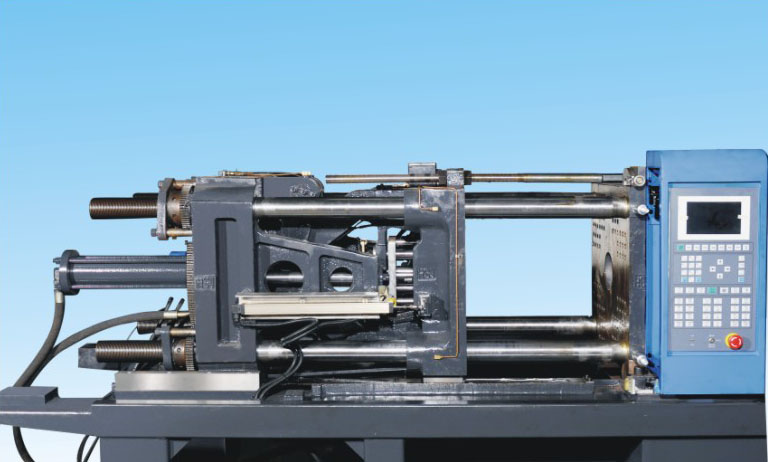

Model NO.: PSJ-90 Type: Injection Blow Molding Structure: Horizontal Plastic Type: Thermoplastic Plasticizing Way: Screw Type Clamping Way: Mechanical Automation: Automatic Computerized: Computerized Certification: CE, ISO9001:2008 Clamping Force: 900kn Injection Weight: 128~177 Gram Clearance Between Tie Bars: 160*160 mm Max

Mould Height: 360 mm Min Mould Height: 150 mm Machine Dimension: 3.95*1.15*1.7 M Machine Weight: 3.5 T Trademark: Plastar Specification: CE Origin: China PSJ-90

Injection Molding Machine with servo

The variable pump from prestigious company, YUKEN VICKERS with the advantages of amoothly running and silence hydrqulic system.

Special design to advoid noise

Save 30-50% energies, especially for long produce ciecle product it will save more.

By circle filter, prolong oil life and ensure hydraulic elements running normal.

Also can save much cooling water as the variable pump system is less relieve hot.

Clamping Unit: Arrange obliquely five-point and elbow type structure. Optimization design on parameter of the computer. Finite-element analysis is applied to design the plates. The unit also functions of low pressure mold protection with extra sensitivity. Machinery, electric pair of safe protection function to insure the safety;

Oil motor :drive the gear to adjusts mold, the moving ahead simultaneously is good and can adjusting the mold automatically according to the pressure set up, very convenient and reliable;

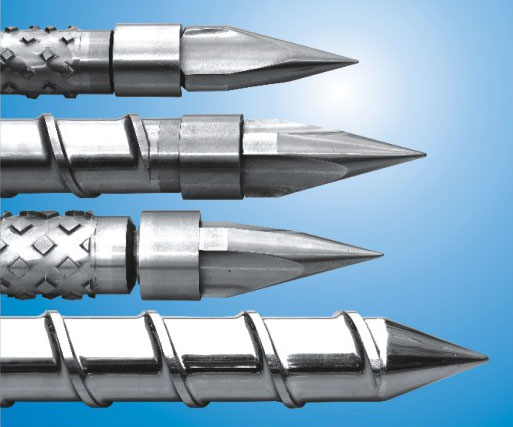

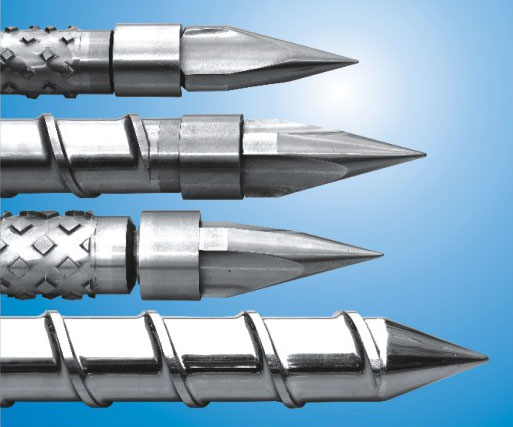

Injection Unit: Double guiding rod supporting. Dual-cylinder balance injection system, Single-Cylinder push and draw back setting. Multi-stage pressure & speed injection. One string hydraulic motor setting. Super quality steel screw stem mixed with chrome, molybdenum and aluminum and barrel disposed by nitrogen. Suitable for every kinds of plastic raw material;Computer Controlled: According imported computer which special for

injection machine. The function is powerful and controlled by CPU, improve the speed in control system and the alarm on over-temperature. Improve the working speed of machine;

Hydraulic Unit: Adopt imported advance hydraulic components;

Lubricating System;Storing type on automatic lubricating system of oil;

With quick response and steady capability, servo gearshift dynamical control system has equipped with pressure feedback device with high precision and sensitivity, which forms a close loop precision control and provide products with high stability;Servo energy saving : Servo energy saving injection

Molding Machine to achieve the maximum output, in comparison with conventional hydraulic injection

Molding Machines, their response speed have been obviously quickened and cycle time effectively shortened, improving production efficiency; There is no extra energy consumption due to output volume changes according to load alteration. The phase of holding pressure, servo motor lowers rotate speed and consumes a little of energies. In the phase of cooling, motor doesn't work and consumes no energy. According to different products, servo energy saving injection molding machines will save 20% -80% energy and bring your prominent economic benefit.

PSJ-90

| Device | Item | Model

Unit | PSJ-90 |

| A | B | C |

| Injection | Screw diameter | mm | 34 | 36 | 40 |

| Screw L/D ratio | L/D | 21.7 | 21.1 | 19 |

| Theoretical shot volume | cm3 | 140 | 158 | 195 |

| Injection weight(PS) | g | 128 | 143 | 177 |

| Injection pressure | MPa | 218 | 194.4 | 157.5 |

| Injection rate(PS) | g/s | 59 | 69 | 86 |

| Plastizing capacity(PS) | g/s | 10.4 | 11.8 | 14 |

| Screw speed range | r/min | 0~220 |

| Making-up | Clamping force | kn | 900 |

| Clearance between tie bars | mm | 360×360 |

| Opening stroke | mm | 330 |

| Max mould height | mm | 360 |

| Min mould height | mm | 150 |

| Other | Ejector force | kn | 27 |

| Ejector stroke | mm | 100 |

| Pump power | kw | 11 |

| Heating power | kw | 6.21 |

| Oil tank capacity | l | 180 |

| Machine weight | t | 3.5 |

| Machine dimension | m | 3.95×1.15×1.7 |

Contact us if you need more details on

Plastic Injection Machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about

Injection Moulding Machine、

Plastic Injection. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Injection Molding Machine